Quality control

The quality of the equipment manufactured and our ability to meet all the technical contractual commitments within the agreed-upon deadlines are our best and constant assets.

Our Quality department ensures compliance with regulations, specifications and codes thanks to certified inspectors (COFREND and ASN, TC 1A) who carry out the follow-up the destructive and non-destructive tests required and/or specifically requested such as:

- X-ray and Y-ray [Gamma ray] tests

- Ultrasonic (UT), Phased Array and TOFD [Time of Flight Diffraction] tests

- Magnetoscopic Testing (MT)

- Penetrant Testing (PT)

- Testing and measurements of Ferrite rates (austenitic and austenitic-ferritic duplex stainless steels)

- Hardness tests

- Chemistry control by PMI [Process Mass Intensity] (X-ray Fluorescence) or by spectrometry

- Macrographic and Micrographic tests

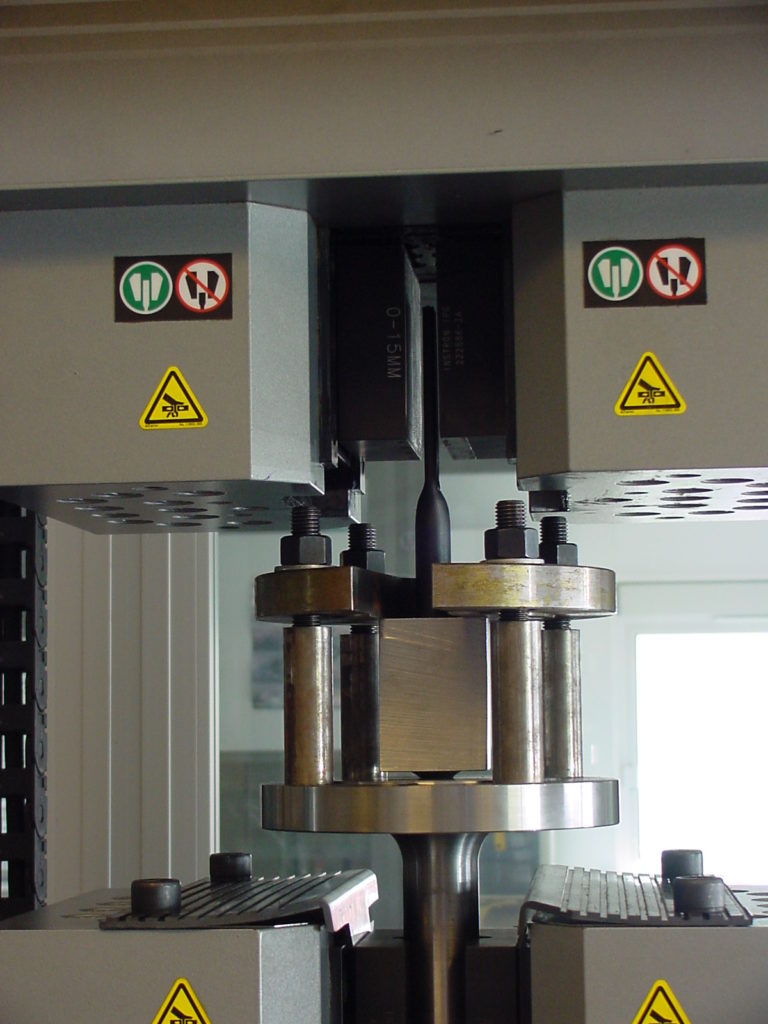

- Tensite tests, bending tests, impact bending tests

- Corrosion testing

- Eddy Current or IRIS testing

- Air, Helium or Vacuum Leakage test

- Endoscopic test

- Hydraulic (up to 650 bars) or air tests

- Hydraulic Test with Acoustic Emission

- 3D Laser Scanning

- Weight Verification (weighing)

- Topometric surveys on site or in the workshops…

At the end of the manufacturing and inspection operations, our Quality Department provides the full final technical documentation for each piece of equipment produced: drawings, calculations, welding book, ITP, final technical documentation, material certificates, destructive and non-destruction test reports, inspection and hydraulic test certifications, coating inspection certificates, operating instructions etc.

In addition to ISO 9001 certification, DELAUNAY & Fils is also U-Stamp and R-Stamp certified by ASME [American Society of Mechanical Engineers] and by the National Board of Boiler & Pressure Vessel inspectors.